EN Free Trial

News Center

Industry News

Gateway helps upgrade the catalyst industry and solve pain points!

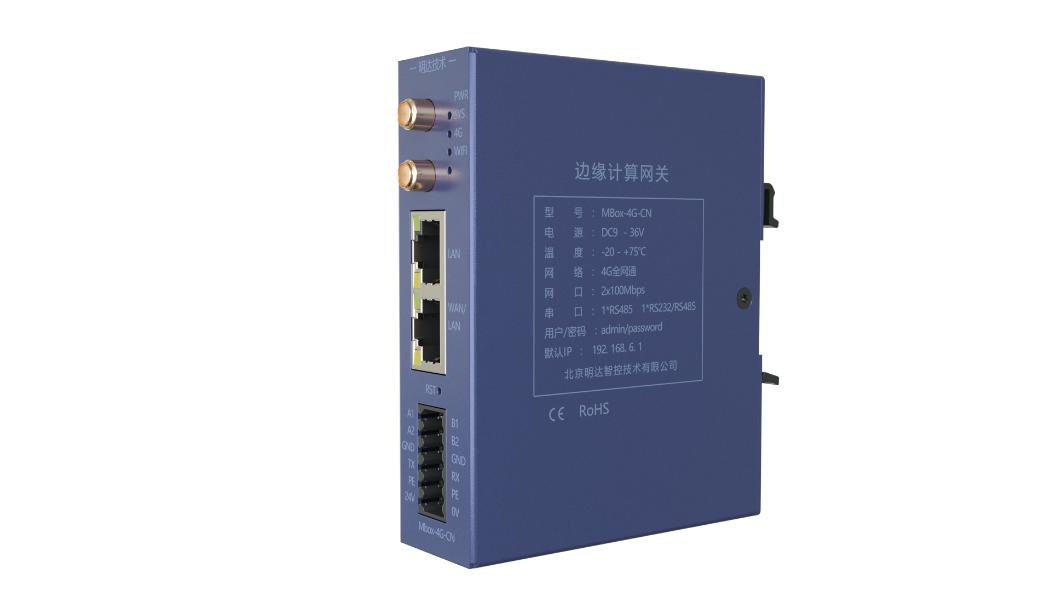

Catalysts, as important mediators that affect chemical reactions, are widely used in various industries worldwide. In addition to the traditional petrochemical industry, catalysts also play a key role in emerging fields such as clean energy development and environmental protection. Mingda Technology has independently developed a new generation of Mbox edge computing gateway to help the catalyst industry upgrade!

Pain points in the catalyst industry:

1. Difficulty in collecting production process data and achieving real-time monitoring;

2. High equipment failure rate, affecting production efficiency and product quality;

3. The phenomenon of isolated production data is severe, with lack of information exchange and difficulty in unified management.

Gateway technology solution:

1. Real time data collection: Gateway devices can collect various data in real-time during the production process, providing strong support for production monitoring;

2. Fault warning and remote maintenance: Through gateway technology, remote monitoring and warning of equipment can be achieved, reducing the failure rate and improving production stability;

3. Data integration and sharing: Gateway helps enterprises break down data silos, achieve unified management and analysis of production data, and improve decision-making efficiency.

Case sharing:

Case 1: Intelligent monitoring enhances production safety. A large catalyst production enterprise has deployed an industrial gateway to achieve real-time monitoring of key equipment on the production line. The data collected by the gateway includes temperature, pressure, flow rate, etc. When the data is abnormal, the system can immediately issue an alarm and automatically take measures. In this way, enterprises can respond promptly in a potential safety incident, avoiding potential economic losses and safety accidents.

Case 2: Optimizing the production process to improve efficiency. A professional catalyst production enterprise utilizes gateway technology to optimize the production process. The gateway connects devices in various production stages, transmitting data in real-time, allowing production management personnel to quickly understand the production status and adjust production plans in a timely manner. Through this method, the production cycle of the enterprise has been shortened by 15%, and raw material waste has been reduced by 25%.

The application of Mingda Technology's gateway products in the catalyst industry not only improves production efficiency and safety, but also reduces operating costs, improves product quality, and provides strong support for the sustainable development of enterprises. We will continue to upgrade and innovate to empower various industries!

Related news

Crane Innovation: Protocol Converter Unlocks Safety and Efficiency

2024/11/01

IO modules help the heavy equipment industry enter a new era!

2024/11/01

Hydrogen Journey: IO Modules Help Reduce Costs and Increase Efficiency

2024/11/01

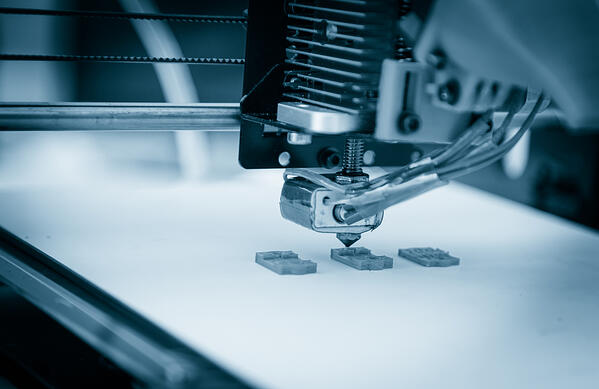

Mingda Technology IO Module: Intelligent Engine for Additive Manufacturing

2024/11/01