EN Free Trial

Heavy Industry Equipment Solutions

Overview of the Plan

The key parameters in the forging process of automotive gears include forging temperature, forging pressure and stroke, forging speed and hammering method, and heat treatment process. Real time collection of key parameters in the forging process of automotive gears ensures precise control of production process parameters, which is of great significance for improving production efficiency, ensuring product quality, reducing production costs, and achieving intelligent production. Therefore, in the forging process of automotive gears, it is necessary to strengthen the monitoring and control of key parameters to achieve the production goals of high efficiency, high quality, and low cost.

Program benefits

Improve production efficiency

By real-time collection of key parameters, abnormal situations in the production process can be detected in a timely manner, such as high temperature, insufficient pressure, etc., so as to adjust production parameters in a timely manner, avoid production interruption and waste generation, and improve production efficiency.

Ensure product quality

Real time collection of key parameters can ensure that all parameters during the forging process are within the specified range, thereby ensuring the quality of the forgings. For example, by monitoring the forging temperature and pressure, it can be ensured that the metallographic structure and hardness properties inside the forging meet the requirements.

lower production cost

By collecting key parameters in real-time and optimizing them, the scrap rate and rework rate can be reduced, thereby lowering production costs. At the same time, real-time data collection can provide strong data support for production scheduling and management decision-making, further improving production efficiency.

Realize intelligent production

Realize intelligent production: Real time collection of key parameters to achieve automation and intelligent control of the production process.

Implement equipment failure model

Real time collection of equipment faults and alarm information, establishment of equipment fault tree model, and rapid handling of equipment faults in the production process.

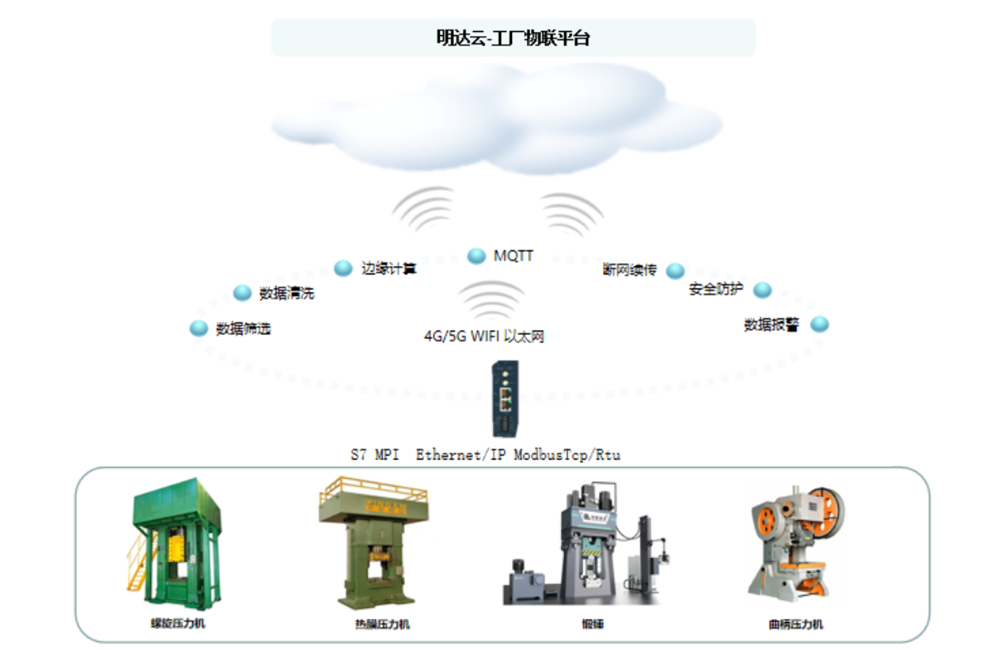

Solution architecture