EN Free Trial

News Center

Industry News

Mingda Technology IO Module: Intelligent Engine for Additive Manufacturing

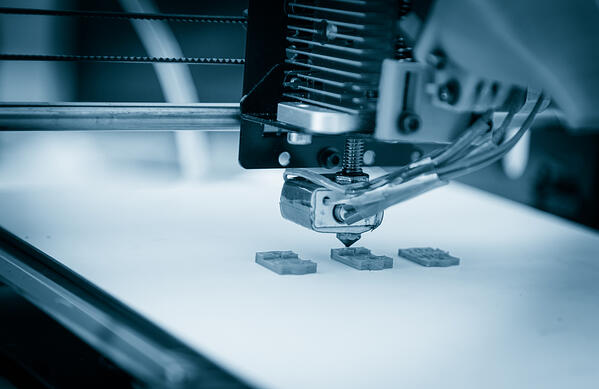

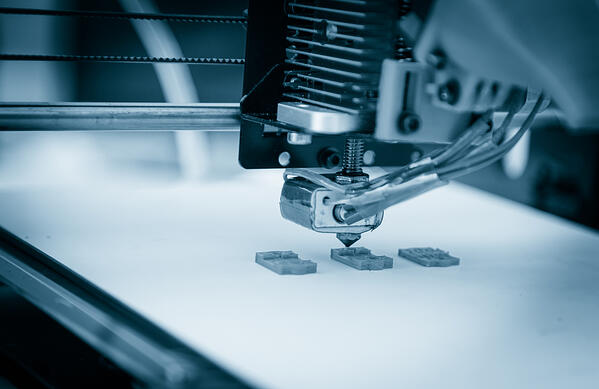

In the rapidly developing field of additive manufacturing (AM), IO modules are becoming an important driving force for technological innovation and efficiency improvement due to their unique advantages. Additive manufacturing, a technology that constructs three-dimensional objects by stacking materials layer by layer, is gradually changing the face of traditional manufacturing. IO modules, as a bridge connecting devices and control systems, are increasingly widely and deeply used in additive manufacturing. Nowadays, Mingda Technology's IO modules serve as a bridge connecting the physical world and the digital world, injecting new vitality into additive manufacturing.

Imagine on precision additive manufacturing equipment, a laser beam precisely accumulates material layer by layer on the workbench, constructing complex and intricate parts. This process not only requires high-precision control systems, but also efficient and reliable data transmission and monitoring. This is exactly where Mingda Technology IO modules come in handy.

Precise control and real-time monitoring

Accurate control of parameters such as temperature, pressure, and material flow rate is crucial in the additive manufacturing process. The IO module can collect real-time data on these key parameters and convert them into digital signals to transmit to the control system, achieving precise control.

Support for diversified communication protocols

Additive manufacturing equipment often comes from different manufacturers and uses multiple communication protocols. IO modules can act as "translators" to convert signals between different devices, achieving seamless integration. This not only simplifies system integration, but also improves compatibility and interoperability between devices. For example, in the additive manufacturing projects of multinational corporations, Mingda Technology's IO modules can ensure smooth communication between devices using PROFINET protocol in Europe and devices using EtherNet/IP protocol in South America, greatly improving the efficiency and flexibility of project implementation.

Remote monitoring and fault diagnosis

With the development of IoT technology, the application of remote IO modules in additive manufacturing is becoming increasingly widespread. Through remote IO modules, enterprises can achieve remote monitoring and fault diagnosis of additive manufacturing equipment. No matter where the device is located, technicians can remotely view the device status in real-time, receive alarm information, and quickly locate and resolve faults. This not only reduces maintenance costs, but also improves the stability and reliability of the production line.

Intelligent and automated upgrades

The application of IO modules in additive manufacturing has also promoted the intelligence and automation upgrade of production lines. By integrating advanced sensors and actuators, IO modules can achieve precise control and optimization of production processes.

epilogue

The application of IO modules in additive manufacturing has brought unprecedented changes and opportunities to this field. Through precise control, diverse communication protocol support, remote monitoring and fault diagnosis, as well as intelligent and automated upgrades, IO modules are helping additive manufacturing enterprises achieve more efficient, flexible, and intelligent production modes. In the future, with the continuous advancement of technology and the expansion of application scenarios, the application prospects of IO modules in the field of additive manufacturing will be even broader.

Related news

Crane Innovation: Protocol Converter Unlocks Safety and Efficiency

2024/11/01

IO modules help the heavy equipment industry enter a new era!

2024/11/01

Hydrogen Journey: IO Modules Help Reduce Costs and Increase Efficiency

2024/11/01

Mingda Technology IO Module: Intelligent Engine for Additive Manufacturing

2024/11/01