EN Free Trial

News Center

Industry News

Hydrogen Journey: IO Modules Help Reduce Costs and Increase Efficiency

Hydrogen energy manufacturing equipment plays a crucial role in the current energy transition, however, this field also faces a series of pain points and issues. The IO module (input/output module), as an important component of industrial automation, can play a crucial role in hydrogen manufacturing equipment. Mingda Technology's independently developed MR20 remote IO module provides an effective solution to these problems and brings significant benefits.

Pain point analysis of hydrogen energy manufacturing equipment

The cost of hydrogen production is high, especially for electrolysis of water, where electricity accounts for a large proportion of the total cost. Key materials such as catalysts and proton exchange membranes are expensive.

Immature hydrogen storage technology: hydrogen molecules have large gaps between them, making compression and liquefaction difficult. The current high-pressure hydrogen transportation method has high costs and limited transportation distances.

Low degree of equipment automation: Traditional hydrogen production equipment relies on manual operation, resulting in low production efficiency and safety hazards.

Insufficient safety protection mechanism: There are dangerous conditions such as high temperature and high pressure during the hydrogen production process, which require a quick response safety protection mechanism.

Mingda IO Solution

Reduce costs: By monitoring real-time parameters such as temperature, pressure, and flow rate during the production process, IO modules can optimize the production process, reduce energy consumption, and minimize material waste.

Combined with advanced control algorithms, IO modules can achieve precise process control, improve the efficiency of hydrogen production through electrolysis of water, and thereby reduce electricity costs.

Improving hydrogen storage technology: Although the IO module itself does not directly improve hydrogen storage technology, it can assist in monitoring the status of hydrogen storage equipment, ensuring the safety and stability of the hydrogen storage process. By connecting with sensors and actuators, the IO module can monitor key parameters such as pressure and temperature of the hydrogen storage tank in real time, and promptly identify and address potential safety hazards.

Improve equipment automation: IO modules can replace manual operation through automated control systems, reduce labor intensity, and improve production efficiency.

Enhanced security protection mechanism: IO modules have fast response capabilities. By connecting with explosion-proof sensors and other devices, IO modules can achieve safe isolation and signal conversion under hazardous conditions, protecting equipment and personnel safety.

Program benefits

Improve production efficiency: Automated control systems can reduce human intervention and improve the stability and continuity of the production process. Accurate process control helps optimize the production process and improve production efficiency.

Cost reduction: Through real-time monitoring and precise control, IO modules can reduce energy consumption and material waste, and lower production costs. Automated control systems can reduce labor intensity and lower labor costs.

Enhanced security: A rapid response security protection mechanism can prevent accidents and protect equipment and personnel safety. Real time monitoring and warning systems can promptly identify and address potential security risks, reducing security risks.

Improving equipment reliability: By connecting with sensors and actuators, IO modules can achieve real-time monitoring and fault diagnosis of equipment status, improving equipment reliability and service life.

summary

The application of Mingda Technology IO modules in hydrogen manufacturing equipment can bring significant solutions and benefits, helping to promote the rapid development and commercialization of the hydrogen energy industry.

Related news

Crane Innovation: Protocol Converter Unlocks Safety and Efficiency

2024/11/01

IO modules help the heavy equipment industry enter a new era!

2024/11/01

Hydrogen Journey: IO Modules Help Reduce Costs and Increase Efficiency

2024/11/01

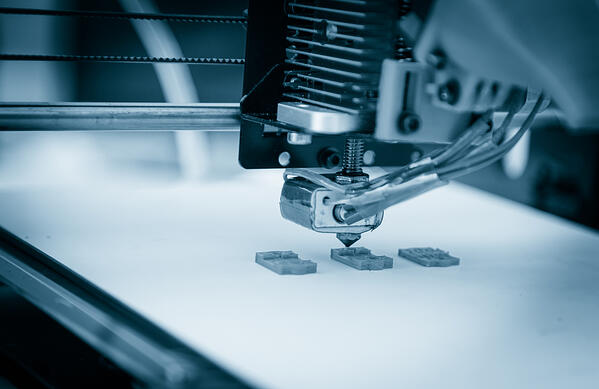

Mingda Technology IO Module: Intelligent Engine for Additive Manufacturing

2024/11/01