EN Free Trial

News Center

Industry News

IO modules help the heavy equipment industry enter a new era!

A traditional heavy equipment manufacturing factory may have roaring machines and splashing iron flowers, but behind this lies problems such as low efficiency, huge energy consumption, and information silos. This is precisely the moment when the IO module shows its full potential. Nowadays, Mingda Technology produces the MR30 series distributed IO and connects on-site devices such as sensors and actuators with IO modules, making real-time data monitoring and precise control within reach.

Pain points in the traditional heavy industry equipment industry:

Equipment aging and high failure rate

In the traditional heavy industry equipment industry, equipment aging and frequent malfunctions are common problems. This not only affects production efficiency, but also increases maintenance costs.

High energy consumption and significant environmental pressure

The heavy equipment industry has high energy consumption, which brings dual pressure to the economic benefits and environmental protection of enterprises.

Low level of informatization and difficult management

Traditional heavy industry equipment enterprises generally suffer from low levels of informatization and serious data silos, leading to difficulties in enterprise management.

Low production efficiency and slow order response

The heavy equipment industry has a long production cycle and slow order response speed, making it difficult to meet market demand.

Solution:

1. Adopting high-performance and high reliability IO modules, real-time monitoring of equipment status, early warning of faults, reducing maintenance costs, and improving production efficiency.

2. By installing intelligent energy-saving IO modules, we can achieve refined energy management, reduce energy consumption, and help enterprises achieve green production.

3. Utilize IO modules to efficiently collect and transmit device data, build an information management platform for enterprises, and improve management level.

4. Adopting automated control IO modules to improve the automation level of the production line, shorten the production cycle, and enhance order response speed.

The application of IO modules in the traditional heavy equipment industry has brought the following value to enterprises:

1. Improve equipment reliability and reduce maintenance costs;

2. Achieve refined energy management and reduce energy consumption;

3. Build an information management platform to enhance the level of enterprise management;

4. Improve production efficiency and shorten order response time.

At a shipyard located in Jiangsu, the introduction of IO module technology has increased production efficiency by 20% and reduced energy consumption by 15%.

The IO module is not just a simple technological product, it is a bridge connecting the physical world and the digital world, and a powerful engine driving the transformation and upgrading of the heavy equipment industry. Just as a drop of water can reflect the brilliance of the sun, a small IO module can also reflect the future glory of the heavy equipment industry.

Related news

Crane Innovation: Protocol Converter Unlocks Safety and Efficiency

2024/11/01

IO modules help the heavy equipment industry enter a new era!

2024/11/01

Hydrogen Journey: IO Modules Help Reduce Costs and Increase Efficiency

2024/11/01

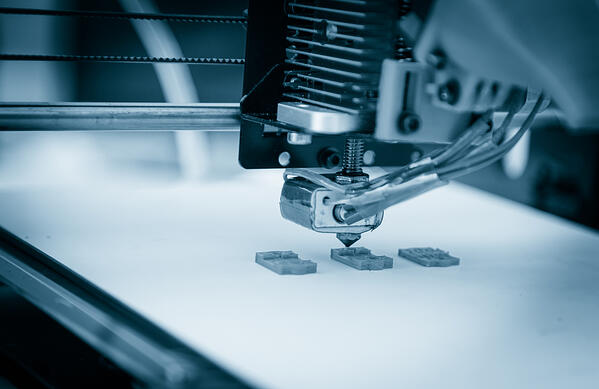

Mingda Technology IO Module: Intelligent Engine for Additive Manufacturing

2024/11/01