EN Free Trial

News Center

Industry News

Remote IO: A Bridge for Efficient Communication and Control between Devices

In today's digital age, remote IO (input/output) technology has become an indispensable part of implementing systems such as industrial automation and smart cities. So, what exactly is remote IO? How does it work? Today, Mingda Technology takes you to explore the secrets of remote IO technology.

What is remote IO?

Remote IO, as the name suggests, refers to the use of remote methods to perform input and output operations on devices. In traditional IO systems, sensors and actuators are usually directly connected to the control system, but in remote IO systems, these devices are connected to a remote controller through a communication network. In this way, even if the device and controller are far apart, efficient data transmission and device control can be achieved. Mingda Technology independently develops and produces the new generation MR20 series integrated IO, which is based on application scenarios where signals are highly dispersed and few in number. It is a compact and integrated product that integrates multiple communication protocols and high-density IO signals. It is a reliable, stable, and diversified integrated product that greatly reduces the cost of the solution while increasing its flexibility.

Working principle of remote IO

The MR20 remote IO module is the core component of the remote IO system, responsible for connecting field devices (such as sensors and actuators) with the control system. These modules collect data from on-site devices and send it to remote controllers through communication networks such as Ethernet, Wi Fi, 4G/5G, etc. Similarly, remote IO modules also receive commands from the controller and pass them on to on-site devices for execution.

The advantages of remote IO

1. Flexibility and Scalability: The MR20 remote IO system supports multiple communication protocols and can be flexibly selected according to needs. In addition, the system is easy to expand by simply adding more remote IO modules.

2. Reduce wiring costs: Since there is no need to directly connect all devices to the controller, it can greatly reduce wiring workload and costs.

3. Improve reliability: Remote IO modules usually have strong anti-interference ability and good stability, which helps to improve the reliability of the entire system.

4. Easy to maintain: Remote IO systems can be monitored and maintained remotely through the network, reducing maintenance difficulty and costs.

Application scenarios

1. Industrial automation: In the manufacturing industry, the MR20 remote IO system can achieve precise control of various equipment on the production line, improving production efficiency.

2. Smart City: In the construction of smart cities, remote IO technology can be used to monitor and manage transportation, environment, public facilities, etc.

3. Remote monitoring: For devices distributed in different locations, remote IO systems can achieve centralized monitoring and management, improving work efficiency.

Remote IO technology, with its unique advantages, is gradually becoming a bridge for achieving efficient communication and control between devices. With the continuous advancement of communication technology, remote IO systems will demonstrate their powerful potential in more fields, bringing more convenience to our lives and work. In the future, let us look forward to more innovation and applications brought by remote IO technology together!

Related news

Crane Innovation: Protocol Converter Unlocks Safety and Efficiency

2024/11/01

IO modules help the heavy equipment industry enter a new era!

2024/11/01

Hydrogen Journey: IO Modules Help Reduce Costs and Increase Efficiency

2024/11/01

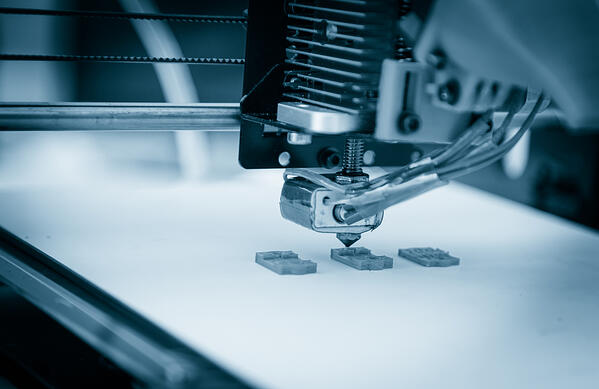

Mingda Technology IO Module: Intelligent Engine for Additive Manufacturing

2024/11/01