EN Free Trial

News Center

Industry News

IO& New Solution for PLC Shaping Packaging Production Line

The packaging industry plays a crucial role in product sales, and can be classified in various ways such as packaging containers, packaging materials, types of packaged goods, and safety purposes. Among them, according to the different packaging materials, they can be divided into paper packaging, plastic packaging, metal packaging, glass packaging, etc; According to different packaging purposes, it can be divided into food packaging, beverage packaging, pharmaceutical packaging, electronic product packaging, etc. China is one of the largest packaging markets in the world, with a huge and continuously growing market size, but also facing some significant pain points. This article will introduce Mingda Technology's MR30 distributed IO and SIEMENS S7-1200 PLC in a simple and easy to understand way to provide solutions and solve pain points.

Analysis of Pain Points in the Packaging Industry

Environmental pressure: With the increasing awareness of environmental protection, consumers and regulatory agencies have increasingly strict requirements for the environmental performance of packaging materials. Resource waste: Excessive packaging leads to the waste of a large amount of materials and resources.

High transportation costs: The large volume of packaging materials results in wasted transportation space and increased costs. Lack of intelligent packaging technology to optimize transportation methods and reduce costs.

Safety issue: Traditional packaging methods may not effectively protect the safety of goods in certain situations.

IO&PLC Solution

Promote intelligent production: By combining S7-1200 PLC with MR30 remote IO module, distributed signal acquisition and control can be achieved. Simplify wiring, improve processing speed, save PLC's own I/O points, and enhance overall efficiency and stability. Automated control systems can reduce human intervention and improve the stability and continuity of the production process. Optimize packaging design: Use IO modules to collect and analyze data during the packaging process, such as material usage, dimensions, etc. Based on data analysis results, optimize packaging design to reduce material waste and lower costs. Intelligent packaging technology: With the help of the Internet of Things and big data technology, the MR30IO module can track and manage the packaging status and transportation route. Real time monitoring of product status during transportation through intelligent monitoring devices, predicting potential risks and taking timely measures.

Improve security: IO modules have fast response capabilities and can be connected to explosion-proof sensors and other devices. Realize safe isolation and signal conversion under hazardous conditions to protect equipment and personnel safety. Strengthen the evaluation and supervision of packaging safety to ensure the safety of goods during transportation, storage, and use.

Summary

Although the application of Mingda Technology MR30 series IO modules in the packaging industry does not directly solve all pain points, it can provide indirect solutions and efficiency improvements for the packaging industry by promoting intelligent production, optimizing packaging design, applying intelligent packaging technology, and improving safety. These measures help reduce environmental pollution, lower resource consumption, improve product packaging quality and safety, thereby promoting the sustainable development of the packaging industry.

Related news

Crane Innovation: Protocol Converter Unlocks Safety and Efficiency

2024/11/01

IO modules help the heavy equipment industry enter a new era!

2024/11/01

Hydrogen Journey: IO Modules Help Reduce Costs and Increase Efficiency

2024/11/01

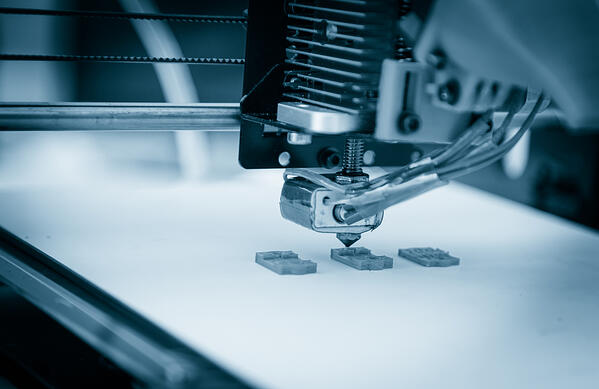

Mingda Technology IO Module: Intelligent Engine for Additive Manufacturing

2024/11/01