EN Free Trial

News Center

Industry News

Local IO and Remote IO: Unveiling the Two Key Roles in Industrial Automation

In the field of industrial automation, IO (Input/Output) modules play a crucial role. They serve as a bridge connecting the control system and on-site devices, responsible for data collection and instruction execution. However, with the continuous advancement of technology, IO modules are also divided into two categories: local IO and remote IO, which exhibit significant differences in multiple aspects. This article will take you through the differences between these two types of IO modules.

Physical location and connection method

Firstly, from a physical perspective, local IO modules are usually directly connected to the PLC (Programmable Logic Controller) host, located within the same physical device, and connected to the PLC host's backplane through dedicated interface modules or plug-in boards. This tight connection method makes data transmission more direct and efficient.

In contrast, remote IO modules are located further away from the PLC host and are connected to the PLC host through communication networks such as Ethernet and serial communication. This connection method requires additional communication modules or device support, but greatly expands the application scope of IO modules, making remote monitoring and control possible.

Transmission distance and signal transmission rate

In terms of transmission distance, the transmission distance of local IO modules is relatively short, limited by the length of the backplane and the physical characteristics of the cables. The remote IO module can be connected through a network to achieve longer transmission distances, and can even span multiple geographical locations, providing great convenience for remote monitoring and control.

Application scenarios and advantages

Local IO modules are suitable for scenarios that require high real-time and stability, such as critical control points on production lines. They can ensure fast data transmission and accurate execution of instructions, providing strong support for the stable operation of the production line.

The MR30 series remote IO module from Mingda Technology has been widely used in various fields such as industrial automation, smart homes, energy monitoring, and environmental monitoring due to its flexibility and scalability. They achieve remote monitoring and control through the network, which not only improves operational efficiency, but also reduces costs and simplifies system deployment. Especially in scenarios that require cross regional monitoring and control, remote IO modules are indispensable and important equipment.

epilogue

In summary, there are significant differences between local IO and remote IO in terms of physical location, connection method, transmission distance, signal transmission rate, and applicable scenarios. They each have unique advantages and applicable scenarios, playing an irreplaceable role in the field of industrial automation. With the continuous advancement of technology and the expansion of application scenarios, we have reason to believe that these two types of IO modules will continue to play a more important role in the future, promoting industrial automation to a higher level.

Related news

Crane Innovation: Protocol Converter Unlocks Safety and Efficiency

2024/11/01

IO modules help the heavy equipment industry enter a new era!

2024/11/01

Hydrogen Journey: IO Modules Help Reduce Costs and Increase Efficiency

2024/11/01

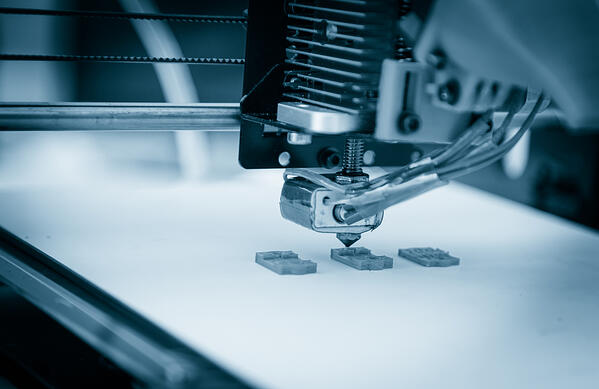

Mingda Technology IO Module: Intelligent Engine for Additive Manufacturing

2024/11/01