EN Free Trial

News Center

Industry News

New generation IO module: Intelligent Future, worry free and efficient choice for faults

In the wave of industrial automation and intelligent control, Mingda Technology IO modules have become a bridge connecting the real and digital worlds with their excellent performance and stability. But in the face of complex and ever-changing operating environments, how to quickly and accurately diagnose and solve IO module faults is the focus of every engineer's attention.

Product advantages

Intelligent control and precision: Mingda Technology's IO module serves as the nerve center of the device, capable of real-time collection of sensor data and precise control of every action of lifting equipment or other industrial equipment. Hot swappable function and maintenance convenience: Mingda IO modules support hot swappable function, which means that quick maintenance can also be achieved during device operation. Without the need for downtime, faulty modules can be easily replaced, greatly reducing maintenance costs and ensuring production continuity. This characteristic is particularly important for enterprises pursuing efficient production. Modular design and easy installation: For example, Mingda Technology's MR30 distributed IO adopts modular design, which has the characteristics of high integration and easy installation. This design not only reduces installation difficulty and cost, but also improves the maintainability and scalability of the system. Diversified communication protocol support: Mingda IO modules support multiple communication protocols, such as Modbus RTU, Modbus TCP, etc., making it easy to collaborate with devices of different brands and models.

New strategy for fault diagnosis

We deeply understand that time is efficiency, and failures are challenges. Therefore, the Mingda Technology IO module is equipped with an advanced fault diagnosis system that instantly locks in the source of the problem, making fault diagnosis no longer blind. Whether it's signal abnormalities, communication interruptions, or hardware failures, clear instructions can be quickly provided, making maintenance simple and efficient.

Remote support, worry free service

What's even more exciting is that our equipment supports remote debugging and maintenance. No matter where you are, with just one click of connection, our professional engineers can assist remotely in fault diagnosis and repair, greatly reducing downtime and ensuring the continuous and stable operation of the production line.

Our IO module products have demonstrated strong competitiveness and broad application prospects in the field of industrial automation due to their advantages of intelligent control, flexible expansion, hot plugging, intelligent monitoring, networked communication, high precision, high reliability, modular design, and diverse communication protocol support.

Related news

Crane Innovation: Protocol Converter Unlocks Safety and Efficiency

2024/11/01

IO modules help the heavy equipment industry enter a new era!

2024/11/01

Hydrogen Journey: IO Modules Help Reduce Costs and Increase Efficiency

2024/11/01

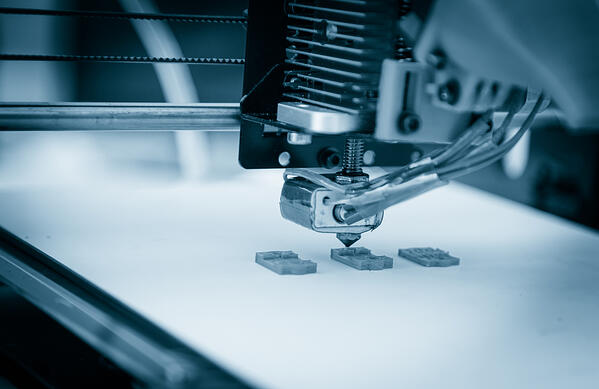

Mingda Technology IO Module: Intelligent Engine for Additive Manufacturing

2024/11/01