EN Free Trial

News Center

Industry News

MR30 distributed IO module: revolutionizing tissue packaging, leading a new era of intelligent and green production

1、 Overview of MR30 Distributed IO Module

The EtherCAT (Ethernet Control Automation Technology) protocol occupies an important position in the field of industrial automation due to its high bandwidth and low latency characteristics. The MR30 distributed IO module independently developed by Mingda Technology is an outstanding application of the EtherCAT protocol, integrating multiple input and output functions. It achieves efficient communication and control with the main station through the EtherCAT bus, bringing innovation to the tissue packaging industry.

2、 Application scenarios and advantages

In the tissue packaging industry, the MR30 module is widely used in key equipment such as packaging machines and conveyor lines. It monitors packaging speed, paper tension and other parameters in real-time to ensure the stability and efficiency of the packaging process.

The advantage of the MR30 module lies in its high real-time performance: the microsecond level response time of the EtherCAT protocol ensures real-time feedback and control during the packaging process, improving production efficiency.

Flexible configuration: Supports multiple input and output types, making it easy to adjust according to production needs and adapt to different packaging scenarios.

High reliability: A powerful error detection mechanism reduces system failures and improves the stability and reliability of the production line.

Cost effectiveness: Utilize existing Ethernet infrastructure to reduce wiring costs and system maintenance difficulties.

3、 Actual application and effect

A tissue production enterprise has achieved an intelligent upgrade of its packaging production line by introducing the MR30 module. This module monitors various parameters during the packaging process in real-time to ensure stable packaging quality and speed. Production efficiency improvement: The packaging speed is accelerated, the production efficiency is increased by about 20%, and the production cycle is significantly shortened. Product quality improvement: Reduce waste caused by poor packaging, enhance customer satisfaction and brand reputation. Reduced maintenance costs: High reliability and error detection mechanisms reduce system failures, lowering maintenance costs and time.

4、 Future prospects

Looking ahead to the future, the development of MR30 distributed IO modules in the tissue packaging industry will present the following trends: intelligent upgrading: deep integration with cloud computing, big data, AI and other technologies to achieve higher-level intelligent control and optimization. IoT integration: Convenient access to the industrial IoT ecosystem, enabling interconnectivity and collaborative work between devices.

Green Production: Emphasize energy conservation, consumption reduction, and environmental protection to promote the sustainable development of the tissue packaging industry. The MR30 distributed IO module plays an important role in the tissue packaging industry with its excellent performance and wide application prospects, and will continue to promote the intelligent, efficient, and green development of the industry.

Related news

Crane Innovation: Protocol Converter Unlocks Safety and Efficiency

2024/11/01

IO modules help the heavy equipment industry enter a new era!

2024/11/01

Hydrogen Journey: IO Modules Help Reduce Costs and Increase Efficiency

2024/11/01

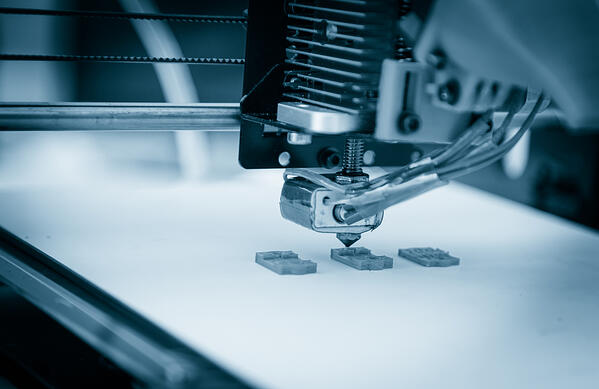

Mingda Technology IO Module: Intelligent Engine for Additive Manufacturing

2024/11/01