EN Free Trial

News Center

Industry News

Mbox Gateway: An Efficient Solution for PLC Data Collection and Communication Challenges

In the field of industrial automation, data acquisition and communication are the core to ensure smooth and efficient production operation. However, automation equipment such as PLCs face pain points such as poor protocol compatibility, low data transmission efficiency, difficulty in remote monitoring and maintenance, and insufficient data security in complex and ever-changing industrial environments. To address these challenges, Mingda Technology has launched the Mbox gateway, providing an efficient and flexible solution for data acquisition and communication of automation equipment such as Siemens PLCs.

Pain point analysis

Siemens PLC has powerful functions, but its communication protocol differs from other brands of PLCs, requiring complex protocol conversion and adaptation during system integration, which increases system complexity and cost, and may lead to unstable or failed communication. Meanwhile, due to limitations in network bandwidth, transmission distance, or device performance, data transmission efficiency may be affected, making it impossible to transmit data in real-time and accurately to the upper system or cloud platform. In addition, traditional monitoring methods for PLC devices distributed in different locations are time-consuming and labor-intensive, increasing the operating costs of enterprises, and the lack of security measures in data transmission and storage may lead to data leakage or malicious attacks.

Mbox Gateway Solution

Extensive protocol access and conversion capabilities: Mbox gateway has extensive protocol access and conversion capabilities, supporting protocol parsing for major brands of PLCs such as Siemens, Mitsubishi, ABB, Schneider, Omron, etc., and converting them into mainstream communication protocols such as MQTT or Modbus, achieving seamless communication between PLCs of different brands and improving the compatibility and flexibility of industrial automation systems. Efficient data collection and edge computing: The Mbox gateway can collect PLC data in real time and conduct intelligent processing through the built-in edge computing function, improving the accuracy and reliability of data. At the same time, the application of edge computing reduces the running pressure of the server and improves the efficiency of data collection and transmission. Multiple data transmission methods: Mbox gateway supports multiple data transmission methods such as 5G/4G/WIFI/Ethernet, and users can freely choose wired or wireless transmission according to their actual needs, ensuring the stability and real-time performance of data transmission. Remote monitoring and maintenance: Through the Mbox gateway, users can remotely upload, download, and monitor PLC programs, reducing after-sales travel costs and improving engineer work efficiency. Cloud platform integration and data analysis: Mbox gateway can connect multiple cloud platforms or industrial configuration software to achieve real-time data upload and cloud analysis.. Through data analysis and application on cloud platforms, enterprises can better grasp various information in the production process, providing more accurate and reliable basis for production decisions.

Summary

With its extensive protocol access and conversion, efficient data acquisition and edge computing, multiple data transmission modes, remote monitoring and maintenance and other functions, Mingda's Mbox gateway has successfully solved many problems faced by automation equipment such as Siemens PLC in data acquisition and communication. This innovative product not only improves production efficiency and reduces maintenance costs, but also enhances the safety and reliability of the system, providing strong support for the digital transformation of factory enterprises and promoting the development of the Industry 4.0 era.

Related news

Crane Innovation: Protocol Converter Unlocks Safety and Efficiency

2024/11/01

IO modules help the heavy equipment industry enter a new era!

2024/11/01

Hydrogen Journey: IO Modules Help Reduce Costs and Increase Efficiency

2024/11/01

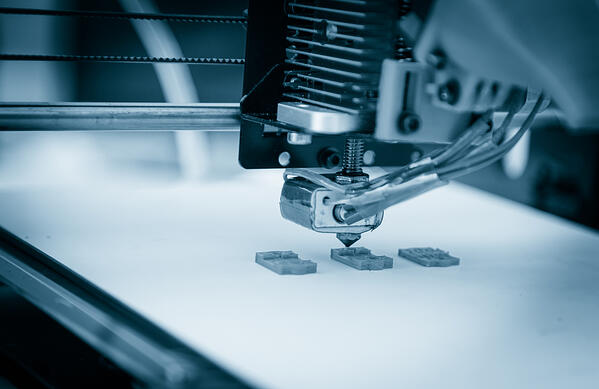

Mingda Technology IO Module: Intelligent Engine for Additive Manufacturing

2024/11/01