EN Free Trial

News Center

Industry News

Automation revolution: how the Mbox edge computing gateway subverts the traditional warehousing industry

In the era of automation and digitization, the warehousing industry is undergoing an unprecedented transformation. With the continuous development of advanced technologies such as artificial intelligence, the Internet of Things, and robotics, the traditional warehousing model is being redefined. Firstly, the application of automation equipment such as automatic handling vehicles, automatic sorting machines, unmanned forklifts, etc. in warehouses is becoming increasingly widespread. These devices not only improve the efficiency of warehousing operations and reduce labor costs, but also greatly reduce the error rate in operations. For example, automatic handling vehicles can automatically transport goods according to preset paths without the need for manual driving, saving manpower and improving transportation efficiency.

The Mbox edge computing gateway independently developed and produced by Mingda Technology, a new generation of intelligent devices for industrial Internet of Things (IIoT) and smart city application scenarios, has brought revolutionary changes to the storage industry. It not only provides powerful data processing capabilities and flexible network connectivity options, but also optimizes for the special needs of the warehousing industry, thereby enhancing the intelligence and automation level of warehousing management.

Faced with challenges such as information silos, high manual error rates, and slow response times, this technology provides effective solutions.

【 Pain Point Analysis 】

Information silo problem: In traditional warehouse management, the phenomenon of information silos between systems is common, which leads to the inability of data circulation and affects decision-making efficiency. Gateway technology can achieve seamless connection between different systems, ensure real-time data sharing, and thus improve overall operational efficiency.

High error rate of manual operation: Manual operation is prone to errors, especially during peak periods. Gateway integrated automation system reduces manual intervention, lowers error rates, and improves job accuracy.

Slow response speed: In emergency order processing or inventory management, the response speed of traditional systems often cannot keep up with demand. Gateway technology can achieve real-time data transmission, accelerate response speed, and improve customer satisfaction.

【Profit Display】

Improving homework efficiency: Through gateway integration, warehouse automation is achieved, reducing manual operations and improving homework efficiency.

Reducing operating costs: Reducing error rates and improving operational efficiency directly lowers operating costs.

Optimize decision-making: Real time shared data supports more accurate inventory management and demand forecasting, optimizing decision-making.

Improving customer satisfaction: Fast response and efficient operations have increased order processing speed and enhanced customer experience.

In the tide of digital transformation, the application of gateway technology in the warehousing industry undoubtedly injects new vitality into the future development of enterprises. We will also further research and innovate to empower various industries and promote the development of digital transformation.

Related news

Crane Innovation: Protocol Converter Unlocks Safety and Efficiency

2024/11/01

IO modules help the heavy equipment industry enter a new era!

2024/11/01

Hydrogen Journey: IO Modules Help Reduce Costs and Increase Efficiency

2024/11/01

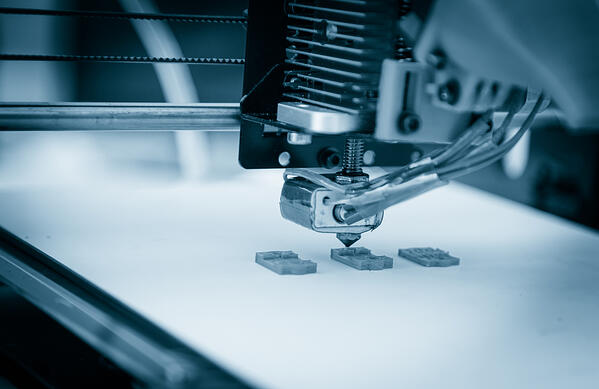

Mingda Technology IO Module: Intelligent Engine for Additive Manufacturing

2024/11/01