EN Free Trial

News Center

Industry News

Slave IO System: Unlocking the Secrets of Distributed Control in Intelligent Manufacturing

In today's industrial automation field, the input/output (IO) system, as an efficient solution, is gradually becoming a key component of distributed control systems. This system greatly enhances the intelligence and efficiency of industrial production by optimizing data exchange and task allocation. This article will popularize the definition and classification of slave IO for you.

What is a stand up IO:

Slave IO (Input/Output) refers to the input/output interface in a distributed control system where each slave device exchanges data with the master station through a specific communication protocol. In this system, the master station is usually responsible for sending control instructions and monitoring the status of slave station equipment, while the slave station is responsible for executing specific input-output tasks, such as collecting sensor data or controlling actuators.

Why configure slave distributed IO

Suppose there is a project where the distance from the main station to the equipment is relatively far, but we want to control the remote equipment through PLC. At this time, we have to connect the IO module of the main station to the remote equipment for control. If there are many points, the corresponding signal lines will be needed, and even the connected control lines will become very messy. In addition to being inconvenient for staff to connect, if the equipment malfunctions in the future and needs to be repaired, it will also be a very tedious task.

The distributed IO system greatly reduces the number of signal lines by deploying slave stations near remote devices. These slave stations are connected to the master station through a communication line, which usually uses industrial communication protocols such as Ethernet, Profibus, Profinet, etc. In this way, the master station can not only receive information from the slave stations, but also send control commands to achieve real-time monitoring and control of remote devices.

The advantage of this system is not only that it simplifies wiring, but also improves the reliability and maintainability of the system. In terms of fault handling, due to the real-time status information provided by the slave station, technicians can quickly locate problems and reduce maintenance time. In addition, distributed IO systems typically have better scalability, making it easier for future system upgrades and expansions.

Application scenarios

Factory automation: used for controlling various sensors and actuators on the production line.

Process control: Monitoring and controlling various parameters in the production process of industries such as chemical and petroleum.

Building automation: used for controlling lighting, air conditioning, security and other systems.

The design and implementation of distributed slave IO systems need to consider various factors, such as system reliability, real-time performance, scalability, etc., to meet the needs of different industrial applications. In China, with the continuous development of intelligent manufacturing and industrial Internet, the application of distributed slave IO technology is more and more extensive.

Related news

Crane Innovation: Protocol Converter Unlocks Safety and Efficiency

2024/11/01

IO modules help the heavy equipment industry enter a new era!

2024/11/01

Hydrogen Journey: IO Modules Help Reduce Costs and Increase Efficiency

2024/11/01

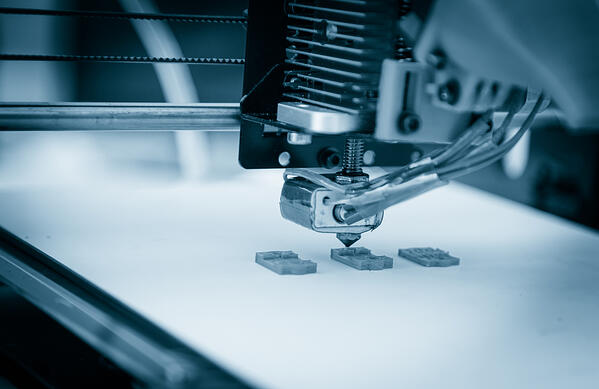

Mingda Technology IO Module: Intelligent Engine for Additive Manufacturing

2024/11/01