EN Free Trial

News Center

Industry News

Integrated remote IO: a new engine for digital transformation in the textile industry

In the textile industry, an ancient and vibrant land, every leap in technology profoundly changes production modes and efficiency. With the rapid development of textile technology and the increasing cost of labor, textile enterprises are actively seeking to reduce production costs and enhance market competitiveness through automation and intelligent means. The introduction of integrated remote IO (input/output) technology is an important force in this transformation process.

The current situation and challenges of the textile industry

The textile industry, as an important component of traditional manufacturing, has long faced problems such as low production efficiency, high labor costs, and high labor intensity. Especially in key processes such as warp threading, warping, and sizing, traditional manual operations are not only inefficient, but also difficult to ensure the stability and consistency of product quality. In addition, with the increasing diversification of market demand, textile enterprises also need to respond quickly to customer orders and shorten delivery cycles, which undoubtedly puts higher demands on the flexibility and automation level of production processes.

The advantages of integrated remote IO technology

The integrated remote IO technology has shown great potential in the textile industry due to its compact structure, convenient installation, powerful scalability, and stable communication performance. This technology integrates various functions such as digital quantity, analog quantity, temperature module, encoder module, etc. through an integrated design, achieving real-time monitoring and remote control of textile equipment status.

Specifically, its advantages are mainly reflected in the following aspects:

Improving production efficiency: The integrated remote IO technology can collect real-time operation status and production data of textile equipment, optimize production plans through data analysis, reduce equipment downtime and material waste, thereby improving production efficiency.

Enhance quality control: Utilize machine vision and artificial intelligence technology for real-time quality inspection of textiles, combined with integrated remote IO technology to achieve rapid data transmission and processing, which can quickly identify and correct defects and deficiencies in the production process, ensuring the stability and consistency of product quality.

Reduce labor intensity: Replace traditional manual operations with automation and intelligence, reduce employee labor intensity, and improve the comfort and safety of the working environment.

Enhance flexibility: The integrated remote IO technology has strong scalability and can flexibly configure functional modules according to production needs, meeting the diverse production needs of textile enterprises.

Application example: Successful application of Mingda MR20 IO module in the textile industry

The MR20 module, as an outstanding representative of integrated remote IO technology, has achieved significant results in the application of the textile industry. Taking the warp threading process as an example, the combination of Mingda Technology's MR20 series products and PLC greatly improves the control accuracy and stability of the warp threading machine. The MR20 series integrated IO products have won widespread praise from customers for their compact size, convenient installation, and stable communication performance. By monitoring the working status and temperature of structural components of the warp knitting machine in real-time, the smooth progress of the warp knitting process is ensured, and the quality and production efficiency of warp knitting are improved.

epilogue

As an important tool for digital transformation in the textile industry, integrated remote IO technology is leading textile enterprises towards more efficient, intelligent, and flexible production modes. With the continuous advancement of technology and the expansion of application scenarios, we have reason to believe that the future of the textile industry will be even brighter. Let's join hands and embrace the beautiful tomorrow of digital transformation in the textile industry!

Related news

Crane Innovation: Protocol Converter Unlocks Safety and Efficiency

2024/11/01

IO modules help the heavy equipment industry enter a new era!

2024/11/01

Hydrogen Journey: IO Modules Help Reduce Costs and Increase Efficiency

2024/11/01

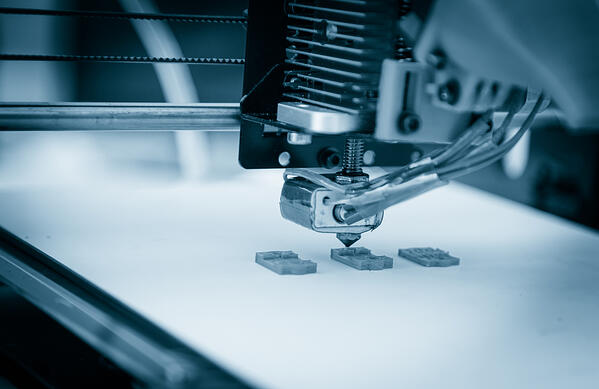

Mingda Technology IO Module: Intelligent Engine for Additive Manufacturing

2024/11/01