EN Free Trial

Robot and non-standard production line industry solutions

Overview of the Plan

HL Precision Manufacturing Company is a professional enterprise engaged in high-end precision mechanical parts processing, with multiple modern processing workshops. In recent years, with the intensification of market competition and technological progress, HL has realized the need to accelerate its own digital transformation pace to improve production efficiency, reduce costs, and ensure product quality. Therefore, HL has decided to deploy a large number of integrated IO modules and IIOT software platforms in the core process equipment of its precision machine tool machining workshop to achieve comprehensive management of robots and non-standard automated production lines

Program benefits

Reduce costs and increase efficiency

By deploying a large number of industrial control IO modules within the workshop to collect various operational data of production equipment. Automated production line reduces 32 people and recovers costs in less than 3 years. Solved the issue of production increase during peak periods

Efficient control

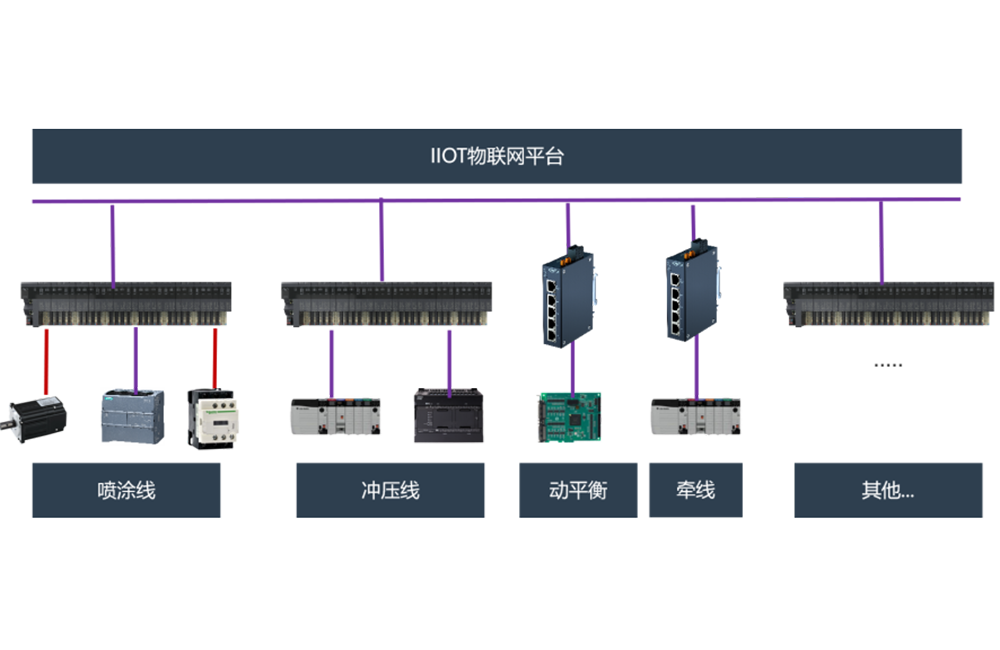

HL has built an IIoT platform based on cloud technology, which integrates various functions such as device management, data analysis, and remote monitoring. Through this platform, technicians can access equipment information in the workshop anytime and anywhere, and remotely control and adjust it. Solved workshop management issues, enhanced enterprise digital operation management level, and expanded enterprise digital management in the future

Solution architecture

Related products

Related Cases

Application of Mingda distributed and integrated remote IO in the industrial robot industry