EN Free Trial

New energy industry solutions

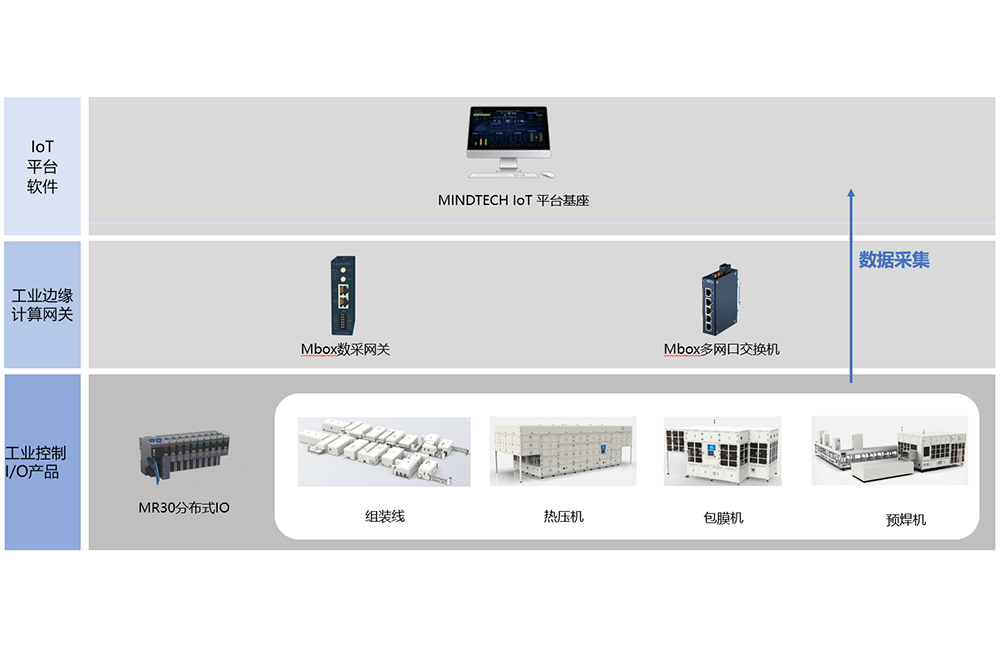

Overview of the Plan

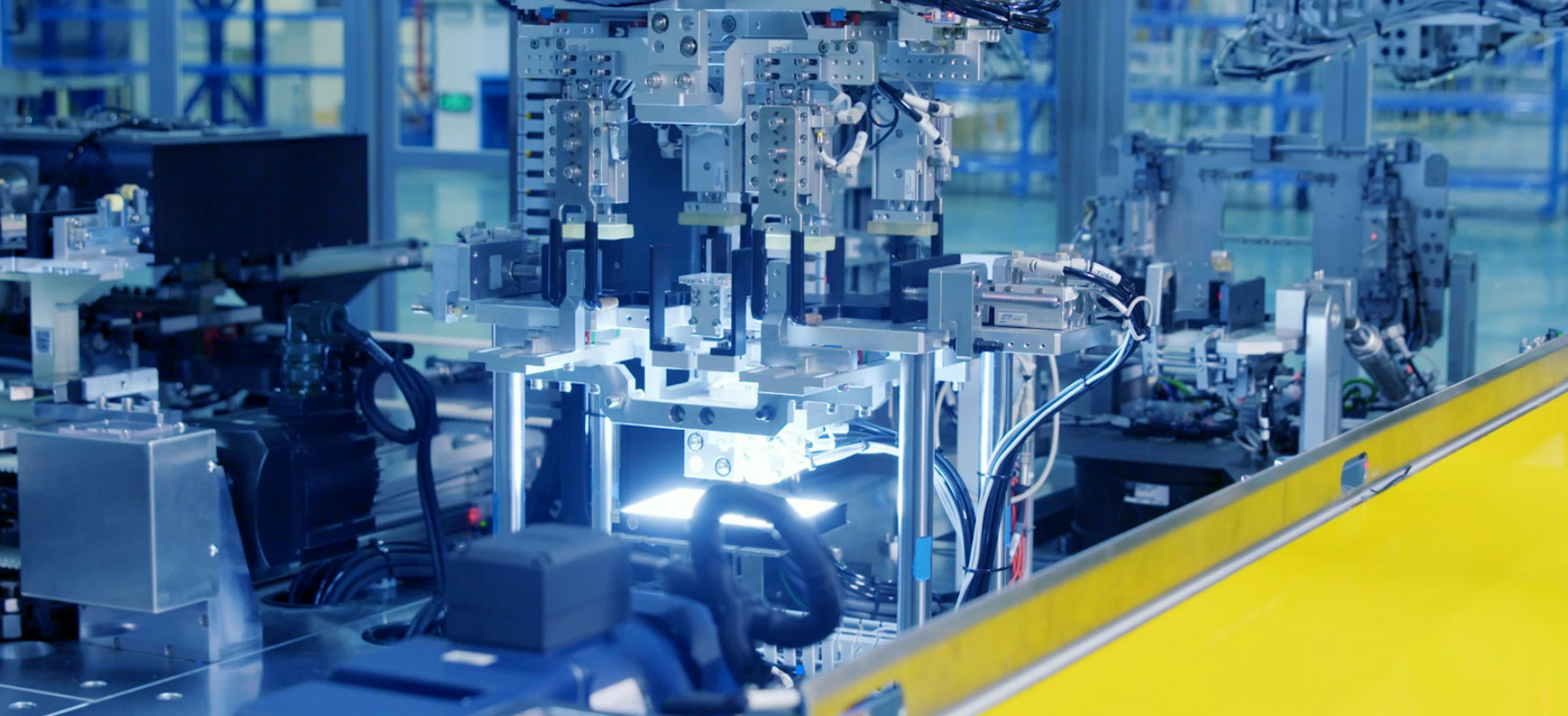

The square shell battery cell assembly line is a key equipment used for producing automotive power batteries and energy storage lithium batteries. It mainly includes hot press machines, pole ear pre welding matching machines, pole ear ultrasonic welding machines, adapter laser welding machines, Mylar coating machines, etc., to ensure the accuracy and efficiency of battery cell assembly. The equipment on the assembly line adopts Omron NJ501 series PLC, whose IO can be replaced with Mingda's MR30 distributed IO module with EtheCAT protocol. At the same time, it is matched with Mingda IOT platform base to achieve one-stop connection, which can efficiently create a digital workshop and realize factory intelligence.

Program benefits

High cost-effectiveness

Domestic IO can perfectly replace Omron PLC's built-in IO module, reducing costs; The IO module supports free hot swapping, making it convenient for users to use and replace during operation and maintenance.

Strong scalability

The IO module supports multiple protocol extensions, the IOT platform base supports multiple protocol docking, and both software and hardware support customized design to meet the vast majority of industrial scenarios.

Rich applications

The IOT platform base supports data collection, visualization, statistical analysis, reporting, etc., meeting various monitoring and management needs of factories; At the same time, mature application products such as equipment management, energy management, production management, and safety management can be provided to enhance the level of digital management

One stop software and hardware integrated solution

Adopting Mingda's comprehensive software and hardware solution, laying the foundation for the digital development of enterprises through a one-stop service that integrates software and hardware

Solution architecture