EN Free Trial

Environmental industry solutions

Overview of the Plan

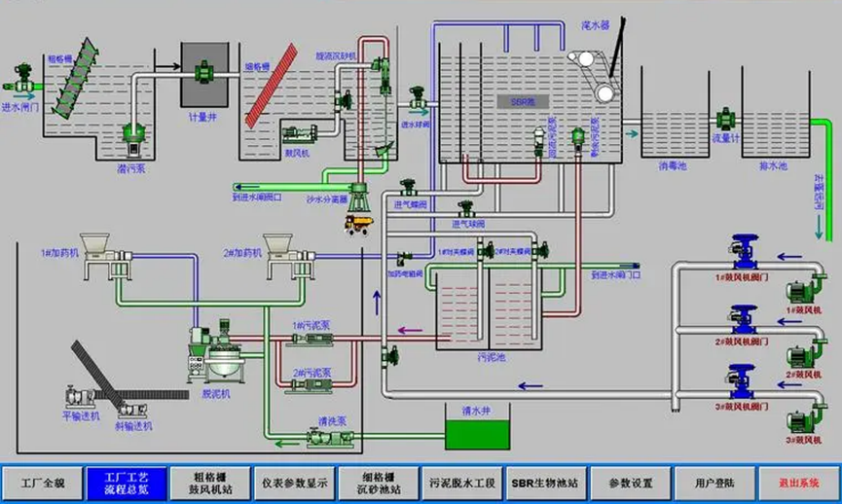

PLC, as the core equipment in the field of industrial automation, I/O control is an important part of PLC application and plays a crucial role in sewage treatment systems. Based on the requirements of sewage treatment processes, the required input (I) and output (O) points are determined. The input points may include sensor signals (such as flow rate, water quality, dissolved oxygen, liquid level, etc.), while the output points include control signals for equipment such as pumps, valves, aerators, and mixers. And according to the set control logic, control the switch status of the equipment to achieve automatic control of the sewage treatment process.

Program benefits

High cost-effectiveness

Domestic I/O modules have a price advantage compared to imported products, which can reduce the equipment procurement cost of sewage treatment plants. Meanwhile, domestically produced modules are not inferior in performance to imported products, and even have advantages in certain aspects.

Stability performance

The domestically produced I/O module adopts advanced hardware and software technology to ensure the stability and reliability of the system. In harsh industrial environments, domestically produced modules can still maintain good working performance, ensuring the stable operation of sewage treatment plants. Flexible and easy to use: Domestic I/O modules have flexible scalability and ease of use, making it convenient for sewage treatment plants to upgrade and expand their systems according to actual needs.

Multi protocol integration

The domestically produced module also supports multiple communication protocols and interface methods, making it convenient to connect and communicate with other devices.

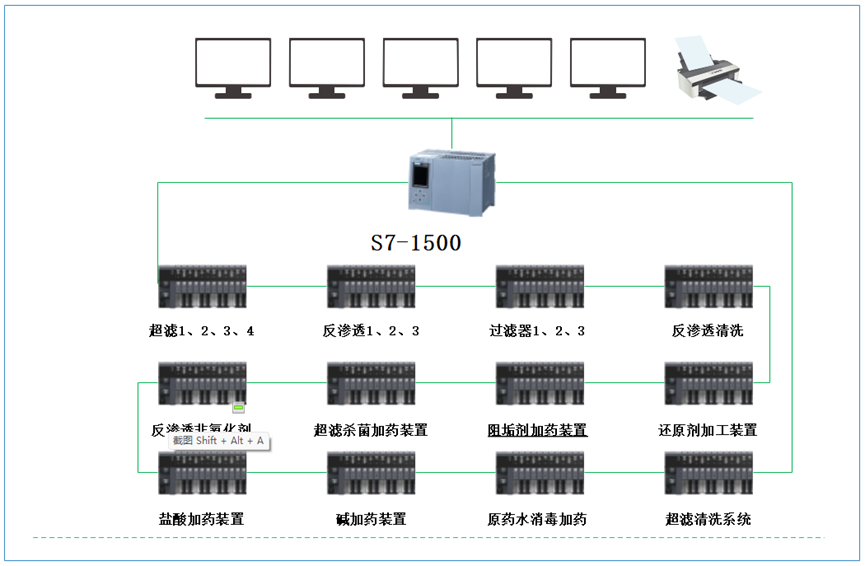

Solution architecture