EN Free Trial

Solutions for the Automotive and Parts Industry

Overview of the Plan

XT New Energy Vehicle Power Motor Factory is an enterprise dedicated to the manufacturing of core components for new energy vehicles. With the rapid development of the new energy vehicle industry, the market has increasingly high performance requirements for power motors, while also posing new challenges to production efficiency and cost control. To address these challenges, LM has decided to use process digitization as a starting point to achieve digital improvement in production.

Program benefits

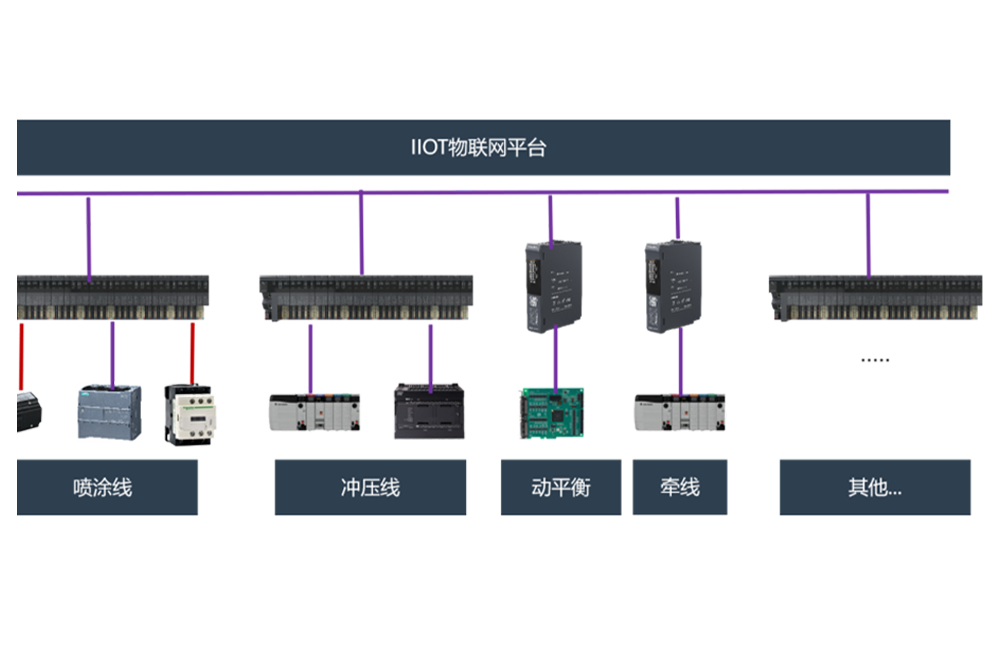

Industrial dual network integration

With the help of RIO and protocol conversion equipment, single device carrying of digital analog signals and industrial communication protocols has been achieved, realizing the organic integration of industrial bus network and production Ethernet, simplifying the data acquisition and integration scheme of conventional devices.

Significant improvement in production efficiency

By leveraging the synergy between the RIO system and the IIoT platform, ABC Company's production line has achieved a high degree of automation and intelligence, resulting in significant improvements in production efficiency compared to before.

Significant reduction in operating costs

Due to the introduction of the fault warning system, the frequency of equipment maintenance has significantly decreased, which can save objective maintenance costs annually. At the same time, the application of material control systems effectively controls material waste and further reduces production costs.

Product quality is guaranteed

Through real-time monitoring and data analysis, XT company is able to promptly identify and resolve quality issues that arise during the production process, ensuring that every power motor leaving the factory meets strict standard requirements.

Significant environmental benefits

Intelligent production not only improves efficiency, but also reduces unnecessary energy consumption, which is in line with the current society's advocacy for green and environmentally friendly production methods.

Solution architecture