EN Free Trial

Solution for Light Industry Machinery Industry

Overview of the Plan

Build a comprehensive IoT platform for sensing, interconnectivity, data sharing, and collaborative integration within the group. Based on the standardized connectivity capability of the Internet of Things platform, achieve full connectivity of digital elements in the group, combine industry knowledge to mine and analyze data elements, and realize data-driven business control and collaboration. The platform provides industry application models that enable collaboration within the group, coordinated management of business, and long-term intelligent upgrading goals.

Program benefits

Paperless office - replacing manual copying

Before the system goes online, the output of each team needs to be manually recorded on the touch screen by the office assistant on site, which is a large workload and has poor data accuracy and authenticity. After the system goes online, production data is collected and statistically analyzed. The production of each team can be immediately pushed to the team leader after the team ends, reducing the workload of employees and ensuring the accuracy and authenticity of key production data.

Improvement of equipment operation and maintenance efficiency

Before the system went online, MES equipment failure work orders were not managed by anyone, and many equipment maintenance issues were not recorded at all, resulting in a black hole in equipment management; After the system goes online, maintenance personnel are required to respond to each alarm message and unplanned shutdown message through alarm data collection, and associate the shutdown reason on MES to ensure transparency in equipment maintenance.

Consolidate the foundation for the informationization construction of the group

Before the system went online, MES could only manage the factory's human, machine, material, legal, and environmental businesses. The lack of data support resulted in a large amount of manual data entry work, and the workload increased instead of decreasing. Employees were very resistant to using the MES system. The group is also unable to achieve transparent supervision of each factory, and the IoT platform has perfectly solved this problem after its launch.

Transparent and centralized control of equipment operation status

After the system goes online, the barrier workers can be informed of equipment abnormalities at any time, and each barrier worker can manage more devices, achieving the effect of reducing manpower; After the system is launched, key data such as quantitative and vehicle speed can be remotely modified through the system, without the need for management personnel to go to the HMI for on-site modification, greatly improving management efficiency and data timeliness and accuracy.

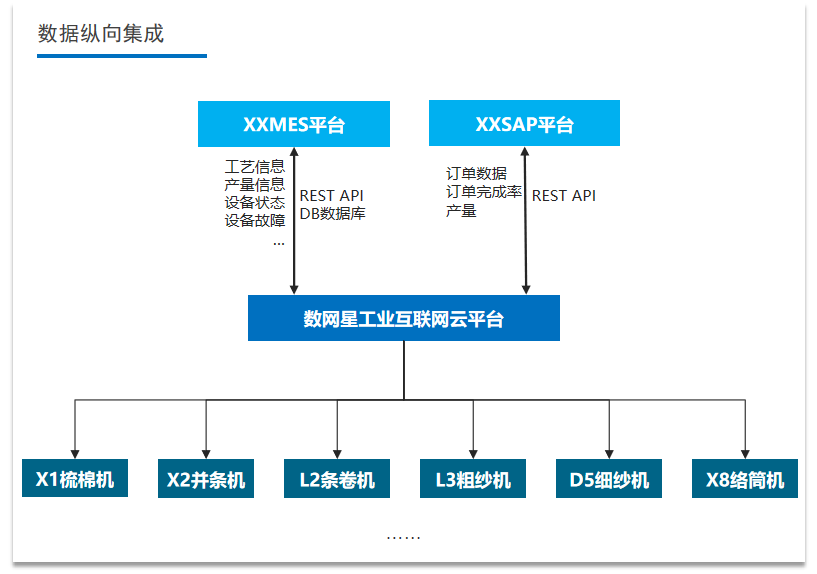

Solution architecture

Support massive data access

The client group has four major bases, nearly 30 factories, and nearly 6000 devices, which support data collection for all factory equipment through one platform;

Support multiple networking methods and multiple collection protocols

There are numerous models of equipment and types of controllers, and the network conditions of new and old factories are different. Data collection needs to be tailored to local conditions;

Group level permissions

Assign different authorities to the leaders of Huafu headquarters, factory directors of each branch, and heads of subordinate departments to implement different management processes;

Group level visualization

Realize multi-level visualization of group factory workshop process section equipment;

Integrate MES and SAP

Coordinate with Huafu Group MES and SAP to provide data support for the above systems and achieve closed-loop management of data;

Group equipment data support

Calculate equipment OEE, power on/off time, and record alarm information and frequency to provide support for equipment management;

Group production data support

Statistics and analysis of production data for each team, monitoring of process data, and statistical analysis of quality data to support production management;

Group Model Management

A factory model can be quickly copied to another factory.

Related products

Related Cases

Application of Mingda Distributed IO&Protocol Converter in Additive Manufacturing Industry